The company Cellfast was founded in 1990 in Krosno. At the very beginning it was a small plant manufacturing garden hoses. Thanks to commitment, persistence and consistency in business activity, within a few years the company has become an important manufacturer in this part of Europe. In order to meet increasing market demands in 2001 we started activity in a newly founded manufacturing plant in Stalowa Wola. This step was a turning point for further dynamic company development. New manufacturing potential allowed us to broaden our present product range and enabled substantial increase of export. In 2003 a new branch of business activity was launched, namely manufacturing of gutter systems BRYZA, and following the same path, of PVC soffits, which enabled to definitely expand operating area of the Group by construction market and over the years established its domestic and foreign market position.

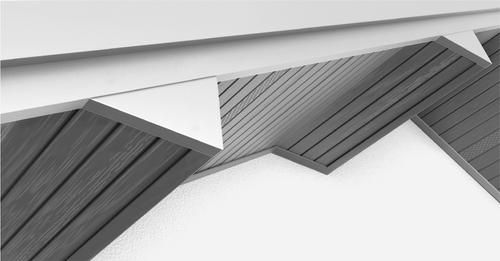

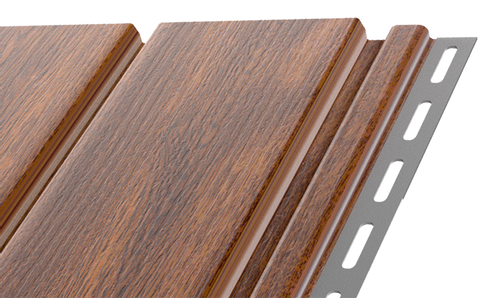

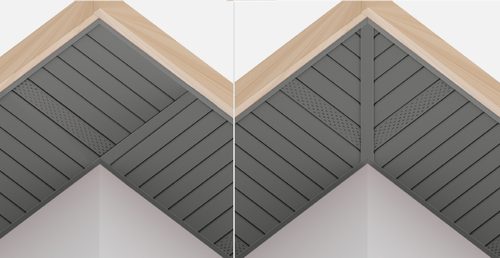

WOOD-LIKE SOFFIT

WIDE RANGE OF COLOURS

Wood-like soffit imitating the natural qualities of wood enjoys an exceptional recognition among customers. Thanks to a wide range of colours, you can easily create an aesthetically pleasing roof eave matching e.g. window and door joinery

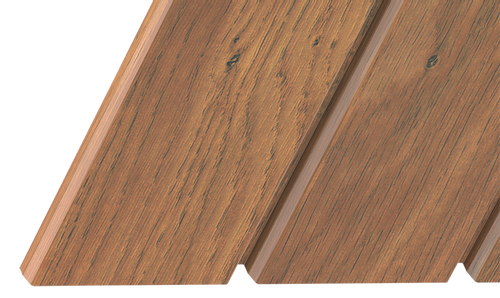

WOOD TEXTURE

COLOUR CONSISTENCY

All the elements have a structure that perfectly imitates the natural qualities of wood. The range of colours of traditional soffit is consistent with the colours of BRYZA gutter systems.

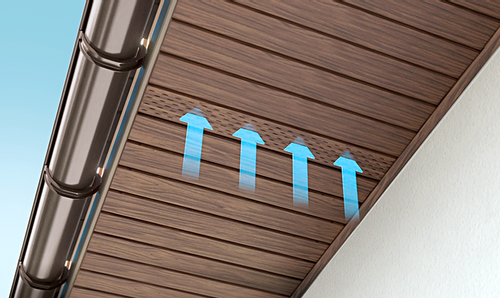

ROOF VENTILATION

LOW WEIGHT

Effective ventilation of the roof slope is a very important element affecting the durability of the entire roof. Perforated panels perfectly fulfil this function. Thanks to the low weight of the system, it is possible to install it on delicate constructions without overloading the roof.

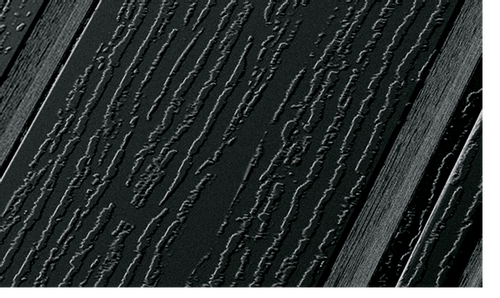

MAINTENANCE-FREE COLOUR FASTNESS

Elements made of maintenance-free material. Even after many years, the roof eave looks like new.

Traditional Soffit

Wood-Like Soffit

Colours

Traditional Soffit

Wood-Like Soffit

Assembly Instructions

1. INSTALLATION OF BRYZA PVC SOFFIT

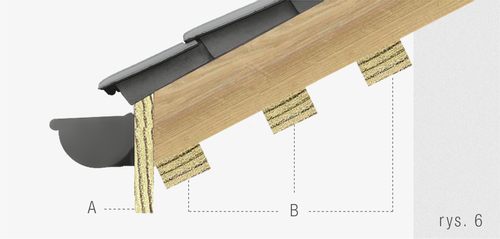

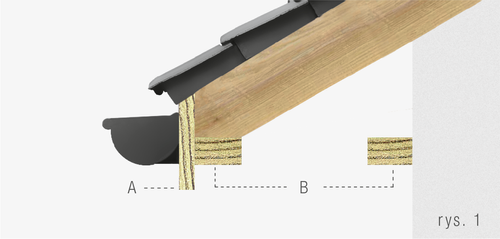

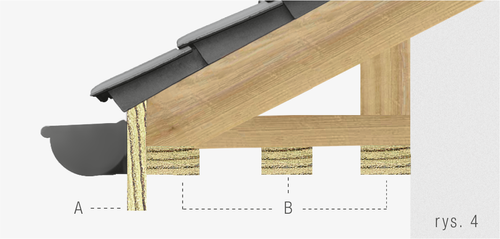

EXAMPLES OF SUPPORTING STRUCTURES

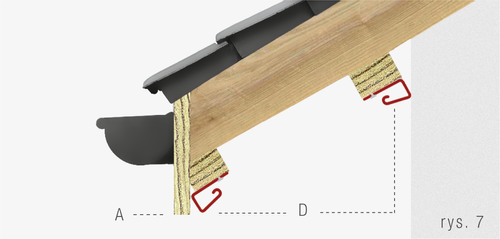

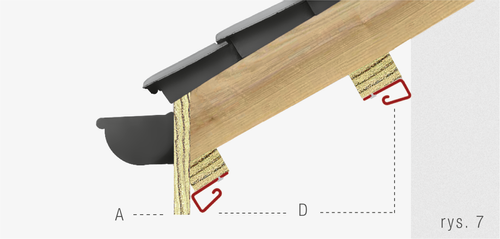

2. EAVES PROTRUSION UP TO 40 CM

3. EAVES PROTRUSION OVER 40 CM

4. INSTALLATION OF A J STRIP

5. CONNECTING J STRIPS

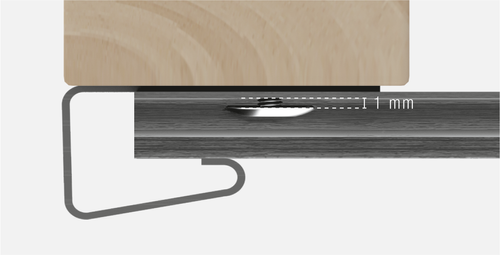

6. INSTALLATION OF SOFFIT ELEMENTS TO SUPPORTING STRUCTURE

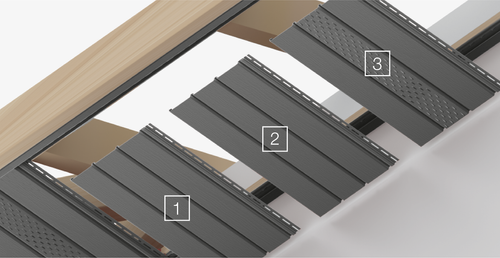

7. INSTALLATION OF PERFORATED BOARDS

8. LOCATION OF H STRIPS

9. CORNER STRIP – OUTER